Application of LED test system

In the LED manufacturing process, electrical, optical, and thermal measurements are performed directly on the production line. Therefore, in the so-called "binning" process, LEDs are divided into quality levels to separate defective products from high-quality products. Although there are strong fluctuations in production batches, each bin contains LEDs with the same photoelectric characteristics. In addition, the results of the online test are used to adjust the production process to increase production.

Conditions and requirements of production test

The main difference between production line testing and laboratory testing is speed. In a production line, approximately ten LEDs are measured per second. The optical measuring instrument must be synchronized with the speed of the production line, and the measuring time must be shortened as much as possible. Insufficient temperature and humidity control on the production line site will also cause great fluctuations. The test equipment needs to be able to run continuously for a long time in the vibration process.

Therefore, high-reliability and low-maintenance equipment is necessary in production measurement, and at the same time, these equipment must be able to provide continuous and accurate results.

LED luminous flux test with integrating sphere

In the measurement of luminous flux, the spatial radiation characteristics of different LEDs means that the emitted light will strike at different positions inside the integrating sphere. Irregular coating and shape of the integrating sphere will cause deviation.

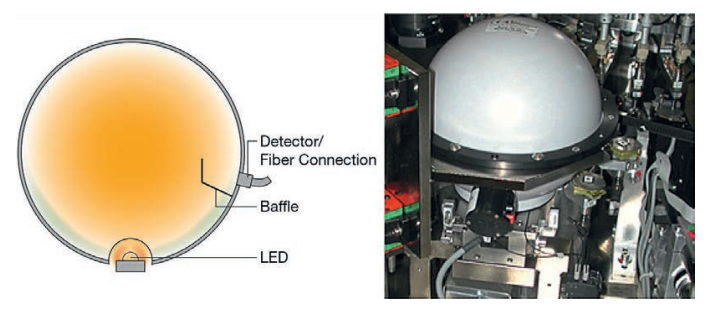

This is why in order to ensure the accuracy of the measurement results, it is necessary to use a high-quality integrating sphere. Since there are no optical elements on the side facing the incoming light, only a uniform barium sulfate coating can reduce the dependence of the measurement direction at this point. The following figure shows the application of the integrating sphere on the production line.

LED light intensity test with sleeve

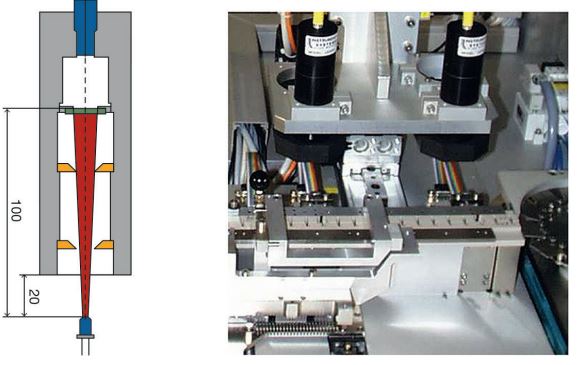

The luminous intensity is measured by a special adapter, the sleeve. The sleeve contains a cosine correction detector with a precisely defined detection area. The LED is placed at a given distance from the sleeve so as not to hinder the movement of the positioner. Therefore, stray light can enter the space between the emitter and the detector, and light from the inside of the sleeve can escape to the outside. This will distort the measurement. Although the detector is shielded by the sleeve housing and two baffles, it is recommended that the measurement environment be sufficiently dark. The measuring port of the sleeve can be protected from dust by a glass plate. The transmittance of the optical fiber connecting the sleeve to the spectrometer may not be affected by mechanical vibration caused by the movement of the positioner. The picture below shows the application of the sleeve on the production line.

Application of VCSEL test system

VCSEL testing on the production line

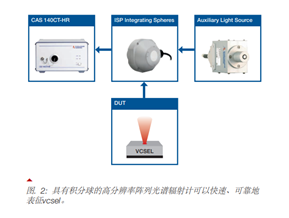

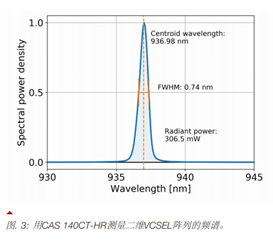

The quality control of VCSEL and EEL in the production line requires complete optical characterization of the device under test (DUT) within milliseconds. For this reason, the combination of integrating sphere (ISP) and a series of high-resolution spectrometers (CAS) is an ideal fast and reliable semiconductor laser diode test system (Figure 2) to determine key properties such as centroid wavelength and radiant power (Figure 2). 3). High measurement speeds require spectroscopy measurements, usually only one millisecond long optical pulse in the time window of the integrated spectrometer.

In such a system, the integrating sphere makes the light field uniform, and the array spectroradiometer provides the necessary measurement speed. For high-precision measurements, it is recommended to use the self-absorption correction method to correct the deviation caused by the wavelength-dependent reflectivity of the DUT. For this reason, it is necessary to choose a suitable auxiliary light source whose spectral power density distribution is appropriate. The narrow spectral bandwidth of VCSEL is generally in the nanometer range, and a spectroradiometer with sub-nanometer spectral resolution is required. The instrument system provides two production-grade high-resolution spectrometer platforms, CAS 140CT-HR and CAS 120-HR, as well as integrated spheres and suitable auxiliary light sources for semiconductor laser diode testing. This makes it possible to provide customers with broadband measurement solutions.

VCSEL testing in the laboratory

Advanced applications in the field of consumer electronics and lidar are driving the vcsel drive pulse time to be shorter and shorter, and the required peak power continues to increase. Currently, standard test procedures drive vcsel with only a few milliseconds long electrical pulses. However, the new test scheme needs to work under nanosecond pulses and several amperes of peak current. Instrument Systems meets this need by providing PVT 100 with an optoelectronic test system for laboratory applications, with driving pulses as short as 1 nanosecond, while providing peak currents of up to 10 amps. PVT 100 uses a multi-sensor approach to make vcsel's complete photoelectric characteristics possible (Figure 4).

main feature:

•High spectral resolution up to 0.12 nm

•PTB traceable measurement

•High sensitivity and high throughput (UPH)

• Integration time as short as 9 ms CAS 140CT-HR 4 ms CAS 120-HR

• Optional auxiliary light source for DUT specific self-absorption correction